The snack food market is a multi-billion dollar industry where success is measured in millimeters and microseconds. This precision is found in the satisfying crunch of a cheese puff, the smooth curl of a maize twist, and the delicate crispness of an airy nibble. While customers enjoy a seamless eating experience, for R&D heads, QA managers, and production supervisors, ensuring every batch of snacks is perfect and consistent is a complex scientific challenge.

The overall extrusion process is a marvel of culinary engineering, but the unsung hero of the finished product is often the corn grit. The particle size of this seemingly simple raw material is what dictates the final snack’s texture, density, appearance, and overall quality.

This official guide will delve into the science behind how selecting the right corn grit impacts every stage of the extrusion process. We’ll show you how a minor change in granulation can revolutionize your final output, your quality control, and your bottom line.

How to Extrude Snack Foods

Before we get into the details, let’s establish a common understanding of the extrusion process. In simple terms, a food extruder is a highly advanced bioreactor. It acts as a continuous high-pressure, high-temperature pump that simultaneously mixes, kneads, shears, cooks, and shapes a product.

As corn grit travels through an extruder, it undergoes a few key stages:

- Feeding Zone: The raw grits and other ingredients are fed into the extruder barrel.

- Mixing and Kneading Zone: Water is added as the screws rotate and push the material forward. The ingredients are blended with water and kneaded to create a smooth, pliable dough.

- Cooking Zone: The combination of mechanical shear and external heat rapidly cooks the dough by raising the pressure and temperature. This is where starch gelatinization, a crucial transformation for the final texture, occurs.

- Forming and Expansion: The dough is forced through a specifically shaped die at the end of the barrel. As it exits, the pressure instantly drops, causing the superheated water inside the dough to flash into steam, puffing the product into its final airy shape.

This entire process is a precise dance between temperature, pressure, moisture content, and screw speed. But the one constant they all interact with is the feedstock itself. And that’s where the true science of corn grit begins.

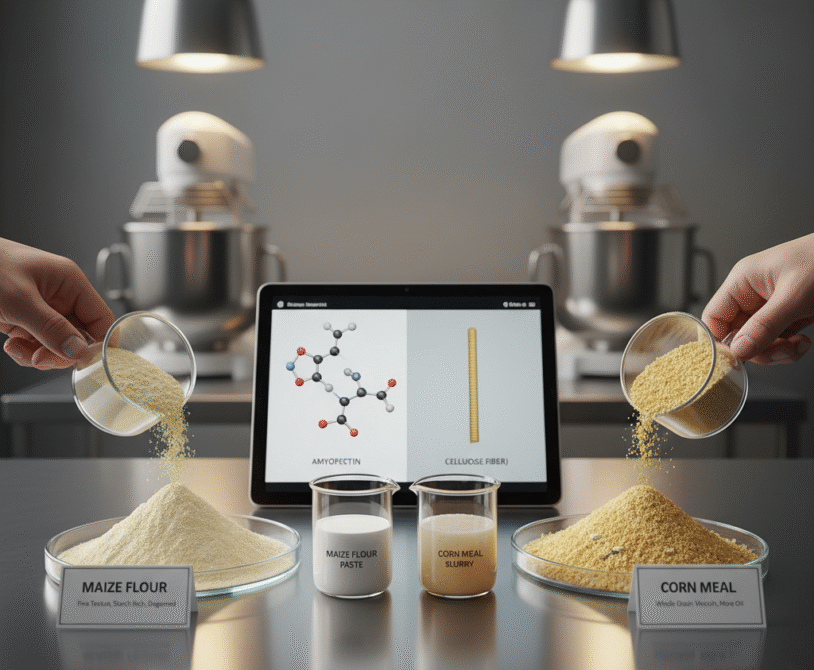

The Heart of the Matter: Understanding Corn Grit

Corn grit isn’t just ground-up corn. High-quality grit from a top corn grit manufacturer is the degerminated and processed endosperm of the corn kernel. Several key properties impact its quality:

- Particle Size Distribution (PSD): This is the most critical factor. It’s not just the average grit size; it’s the range of sizes within a single batch. Is the distribution tight and uniform, or is there a wide range of fine and coarse particles?

- Moisture Content: Typically held between 11% and 13%, this affects how the grit flows and hydrates in the extruder.

- Fat Content: A low fat content (less than 1.5%) is crucial. Improper degermination can lead to excess fat, which hinders water absorption and inhibits the puffing process.

- Bulk Density: This impacts how the material is fed into the extruder and the overall production line capacity.

All of these factors are interconnected, but Particle Size Distribution is the most fundamental because it dictates how the grit will behave in the extreme conditions of the extruder barrel.

The Granular Impact: How Grit Size Affects Extrusion Performance

Let’s follow two distinct grits on their journey: one that is fine and uniform, and one that is coarse or inconsistent. We’ll see how their size affects each critical stage of the process.

1. Dough Formation and Hydration

The first step in the extruder is hydration. At this point, the surface area of the grit becomes immensely important.

- Fine Grits: Because of their greater total surface area, fine grits hydrate quickly and uniformly. This allows for the rapid creation of a smooth, consistent dough with uniform viscosity. The process is predictable and fast, providing you with more dwell time for proper cooking.

- Coarse Grits: Larger particles have a smaller surface area, so they take longer to absorb water. This can result in a dry dough with un-hydrated starch granules. The result is a non-homogeneous mass that lacks the proper rheology (flow characteristics) for smooth processing.

The worst-case scenario is a mix of inconsistent grits (fines + coarse). The fine particles quickly absorb water and can become overly sticky, increasing the workload on the extruder motor. Meanwhile, the coarse particles remain too dry, creating hard spots in the dough. This inconsistency makes the entire process unpredictable.

2. Cooking, Gelatinization, and Melting

The cooking stage is where the starch transformation happens. When heated, starch granules absorb water and swell to form a thick melt, a process called starch gelatinization. This melt provides the structure for the final snack.

- Fine Grits: A consistent dough from fine grits allows for heat and shear to be distributed equally. Since each particle cooks at roughly the same rate, the starch gelatinizes fully and uniformly. This creates a strong, smooth, and consistent starch melt.

- Coarse Grits: The large particles in a coarse grit dough may not get hot enough to fully gelatinize in the short time spent in the extruder. This means the melt will contain unprocessed starch, which weakens the final product.

Inconsistent grits lead to a poor melt. The fine particles might overcook, causing a burnt off-flavor and dark specks in the final product. As mentioned, the coarse particles will remain undercooked. The resulting melt is weak, inconsistent, and riddled with structural flaws.

3. The Moment of Truth: Expansion at the Die

This is where the magic happens. The final size, density, and texture of the food depend on how well it expands. This stage is almost entirely determined by the quality of the starch melt created in the previous phase.

As the superheated water in the pressurized starch melt flashes into steam the moment it exits the die, the mixture expands. This rapid phase change creates bubbles, or cells, that cause the material to puff up.

- Fine Grits (and their uniform melt): A smooth, strong, and continuous starch melt acts like a perfect elastic. It can contain and control the force of the expanding steam, allowing for the formation of a multitude of small, even, and stable cells. This controlled expansion results in a light, airy mouthfeel, a delicate, crispy texture, and maximum product volume.

- Coarse Grits (and their poor melt): Under-gelatinized starch granules create weak spots and fissures in the melt structure. The steam struggles to flash properly. Instead of forming many small bubbles, it breaks through these weak points, creating a few large, irregular cells or channels. The result is uncontrolled expansion, which makes the product hard, dense, and glass-like in texture.

| Feature | Fine, Uniform Corn Grit | Coarse or Inconsistent Corn Grit |

| Texture & “Mouthfeel” | Light, airy, delicate crispness. Melts in the mouth. | Hard, dense, glassy. A tough, often painful “toothy” bite. |

| Appearance | Uniform shape and size. Smooth, appealing surface. | Irregular shapes. Bumpy, cratered surface with potential uncooked specks. |

| Bulk Density & Bag Fill | Low density due to high expansion. Excellent volume, leading to better bag fill and perceived value. | High density due to poor expansion. Requires more product weight to fill a bag. |

| Breakage | Strong cellular structure leads to less breakage during seasoning and packaging. | Brittle, irregular structure leads to high levels of breakage and fines. |

| Flavor Adhesion | The uniform surface allows for even coating of seasoning and oils. | The irregular surface can lead to uneven seasoning, with too much clinging to craters. |

Choosing a Corn Grit Manufacturer as a Partner: It’s Not Just About the Specs

When it comes to creating the perfect extruded snack, achieving consistency is no accident. It’s the direct result of carefully controlling your variables, and the most crucial one is the quality of your corn grit. For a buying manager, the right choice influences yield, breakage rates, and bag fill—all directly impacting the bottom line. For the head of R&D, it’s the difference between a successful product launch and a formulation that never leaves the lab.

Simply ordering a corn grit with a certain micron size isn’t enough to get this level of accuracy. You need to partner with a corn grit maker who understands how to use technology to consistently produce a high-quality product.

The most crucial thing is to get the Particle Size Distribution (PSD) data, not just the average size of the particles. A reputable provider will give you a product with a tight “bell curve” distribution. This implies that most of the particles are extremely close to the right size, with very few fines or coarse outliers. For any snack food manufacturer, this kind of stability from month to month and bag to bag is the holy grail. It cuts down on the need to constantly modify extruder settings and ensures the output is always high-quality and easy to forecast.

The Granular Path to Perfection

The feel of the corn grit is paramount. The size of the food affects how well it cooks, how well it hydrates, how much it expands, and ultimately, how much the customer enjoys it.

Purchasing consistent, precision-milled corn grit is not just a raw material cost; it’s an investment in your product’s quality, your production line’s speed, and your company’s reputation.

Are you ready to make your products more consistent and improve your extrusion process?

Contact the technical team at Parakh Group to discuss your needs and request a sample of our precision-milled corn grits, the ideal foundation for your next great snack.