There’s an undeniable magic to a perfectly brewed lager. It’s the crisp, clean “snap” on the finish, the brilliant clarity in the glass, and the refreshing character that invites another sip. While brewers rightly celebrate the foundational roles of malt, hops, water, and yeast, many of the world’s most iconic and sessionable beers rely on a fifth ingredient—a so-called “secret weapon” that has shaped brewing for over a century: flaked corn grits.

For many modern craft brewers, the word “adjunct” can be a loaded term, often unfairly associated with mass-produced beers of the past. However, the world’s most innovative and quality-focused breweries understand that ingredients like flaked corn are not “fillers,” but powerful tools. When used with intention and skill, they are essential for crafting specific flavor profiles, improving process efficiency, and creating beers of exceptional quality and clarity.

This is a deep dive into the science and art of using flaked corn. We’ll explore its historical roots, unpack the science of gelatinization, detail its profound impact in the brewhouse, and explain what to look for when you buy this vital ingredient from a top corn grit maker.

A Nod to History: The American Adjunct Tradition

To understand why brewers use corn, we must first look to the past. In the mid-to-late 19th century, a wave of German immigrant brewers brought their lager-brewing expertise to America. They were masters of their craft, but they immediately encountered a raw material challenge: the North American six-row barley was fundamentally different from the two-row barley they were accustomed to in Europe.

Six-row barley, while hardy and high-yielding, was significantly higher in protein and enzymes (diastatic power). An all-malt beer made with this barley often resulted in a hazy, full-bodied brew with a satiating, almost chewy character—a far cry from the crisp, brilliant lagers they intended to produce.

Ever resourceful, these brewers looked to locally available grains to solve the problem. They discovered that adding a percentage of adjuncts like corn or rice to the mash had a transformative effect. The corn, being low in protein and high in fermentable starch, effectively diluted the excess protein from the six-row malt. The result?

- A lighter body and color.

- Improved clarity and stability.

- A crisper, drier, and more refreshing finish.

This innovation gave birth to the Classic American Pilsner and, eventually, the American Light Lager styles that would come to dominate the landscape. It wasn’t about cutting costs; it was a great piece of brewing engineering to employ local ingredients to develop a new, very American style of beer.

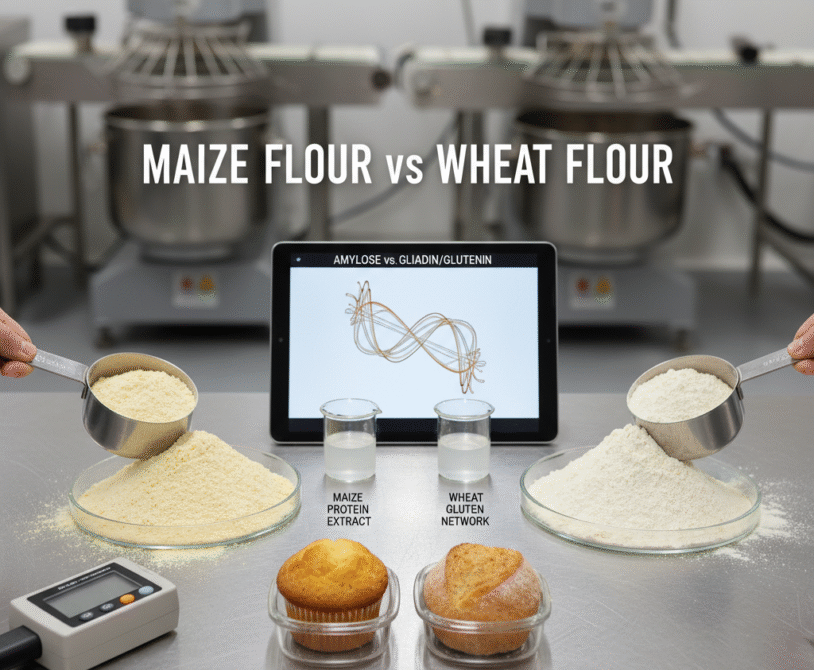

Deconstructing the Ingredient: What Exactly Are Flaked Corn Grits?

Today, brewers no longer have to cope with the hassle of crushing and roasting raw corn. Today’s ingredient suppliers have made the procedure better, so they can always send out a product that is the same, stable, and ready to use. But what happens before the corn grit gets to your brewery?

From Kernel to Flake: A Multi-Stage Process

You need to find the greatest corn before you can manufacture high-quality flaked corn. Here are the steps:

- Degermination: The germ in the maize kernel, which is full of oil, is carefully removed. When brewing, this step is not up for debate. Corn oil can ruin the taste of beer and make it go bad quicker. It can also change the appearance of the beer head.

- Milling: The endosperm that is left over is ground into a certain, even particle size known as corn grit.

- Flaking: After that, the grits go through enormous, heated rollers. This process not only flattens the grit into a thin flake, but it also transforms the starches inside into jelly.

The Power of Pre-Gelatinization

Flaking is the last step, and it’s what makes this component effective in a modern brewhouse. Starch is not available to the enzymes (alpha and beta-amylase) in the mash when it is in its original granular form. To produce it gel, the starch granules need to be cooked in water until they swell, break, and turn into a gel-like state.

In the past, brewers who used raw corn or normal grits had to undertake a separate, time-consuming “cereal mash” in a special cereal cooker to convert the starches into gel before adding them to the main mash.

The maize that has been flaked is already gelatinized. The heat and pressure from the rollers have already done the work. This means that brewers can mix the flakes in with their base malts in the primary mash tun. This saves a lot of time, energy, work, and the need for extra tools.

The Brewer’s Canvas: How it affects the beer and the brewhouse

Adding flaked corn to a dish does more than just save time. It has a huge and predictable effect on how the beer is made and how it tastes after it’s done.

1. Making the Flavor Profile: Looking for “Crisp”

This is the main reason why brewers use corn flakes. Barley malt gives the beer a number of varied tastes, colors, and sweetness. Corn, on the other hand, gives it a simple, nice taste.

- Lightens Body and Color: Corn doesn’t add much color (low SRM) or protein, which makes the beer lighter and less colorful.

- Dries the Finish: Corn’s starches break down into sugars, principally dextrose, that are very easy to ferment. Yeast consumes these simple carbohydrates very well, which raises the attenuation level. This decreases the final gravity and residual sweetness, which gives American Lagers and other types the sharp, “snappy,” and dry finish that brewers prefer.

- Creates a Neutral Canvas: Corn has a clear, neutral taste that helps other flavors come through. It gets out of the way, making it the perfect background for the delicate noble hop smells or the subtle fruity esters of a certain lager yeast strain.

2. Technological benefits of the Mash Tun

Flaked corn tastes good and has several process advantages:

- No Cereal Cooker: As mentioned, this makes everything go more smoothly.

- Protein Dilution: Flaked maize lowers the overall protein concentration, which helps making the wort clearer and less likely to produce chill haze.

- Managing Diastatic Power: Corn doesn’t have any enzymes, but most modern, well-modified base malts (such American 2-Row or Pilsner malt) contain a lot of diastatic power that can easily turn corn into something else.

3. Best Practices and Problems That Could Happen

Even though flaked corn is easy to utilize, experts nonetheless follow a few best practices:

- Fighting a Gummy Mash: Corn doesn’t have a husk, so its gelatinized starches could stay together. It could make the lauter slow or jammed if you use more than 20–25% of it. Many brewers add a small amount of rice hulls on purpose to make sure that the grain bed is porous and that the wort collection runs smoothly.

- Yeast Nutrition: Corn doesn’t supply yeast as much Free Amino Nitrogen (FAN) and other nutrients as an all-malt mash would. When brewers use additional corn, they should make sure that their base malt has enough nutrients. If it doesn’t, they might think about adding a yeast nutrient to assist the fermentation go faster and better.

- Common Rates of Use:

- 5–15%: To add some crispness and lightness to artisan pilsners or Mexican-style lagers.

- 15–25%: For a classic Cream Ale or Pilsner from before Prohibition.

- Up to 40%: This is the taste of a Classic American Lager or Light Lager.

More than simply Lager: How people utilize it now

You can use flaked maize in more than just regular lagers. New ways to employ it are being thought of by modern craft brewers:

- Hazy IPAs: The major ingredients that make the brew hazy and give it a soft mouthfeel are flaked oats and wheat. Some brewers add a little bit of flaked maize to the beer to make it less sweet and change its body.

- Gluten-Reduced Beers: Corn is a major ingredient in manufacturing gluten-free and gluten-reduced beers because it is a grain that does not contain gluten. It is usually mixed with rice, millet, and sorghum.

What to Look for in a Good Corn Grit Maker: Finding what you need with confidence

Consistency is the most crucial factor for a brewery. A 5-gallon homebrew can take small modifications, but a 50-barrel batch has to be perfect every time. This is why the recipe is just as important as the source you choose. When you look for a corn grit maker, look for:

- Unyielding Consistency: The supplier must show that they have full control over their process by sending out flakes that are always the same in terms of moisture level, degree of gelatinization, and composition. Ask for a Certificate of Analysis.

- Purity of Supply: The best flakes come from corn grit that is pure and doesn’t have any other elements in it. Find suppliers who are actually committed to keeping food safe and have food safety certificates.

- A Non-GMO Option: People who drink craft beer these days are often fussy about where their components come from. You can meet this need and tell a great story about how committed you are to getting great products if you collaborate with a supplier who can deliver you a verified Non-GMO product.

- Brewing Knowledge: The ideal provider doesn’t just sell you anything; they also know how you work. They may give you advice, help, and technical knowledge to help you get the most out of their ingredients.

Conclusion: A Modern Brewer’s Strategic Tool

It’s not merely a technique to save money or a footnote in history to eat flaked corn grits. When you know how to utilize them and where to buy them, they are a highly valuable and flexible part that lets the modern brewer produce exactly the results they want. With flaked corn, you may produce beers of the greatest quality, from the clear taste of a Classic American Pilsner to the sharp finish of a contemporary Mexican Lager.

It makes the body lighter, the finish sharper, and enables the brewer’s true art come through, generating beers that are clean and refreshing that customers will want to drink again and again.

Are you ready to improve your crisp lager or come up with a new beer? If you need help, call the specialists at Parakh Group and ask for a technical data sheet for our high-quality, pre-gelatinized flaked corn grits.